Kanban is a way of managing the flow of work, which is based on the philosophy of Lean Management originally used in Japan. The Kanban system uses a visual way of managing the flow of work using visual boards and cards. This approach makes it possible to effectively track and manage work, identify obstacles, waste or bottlenecks and improve the overall work flow.

What is Kanban?

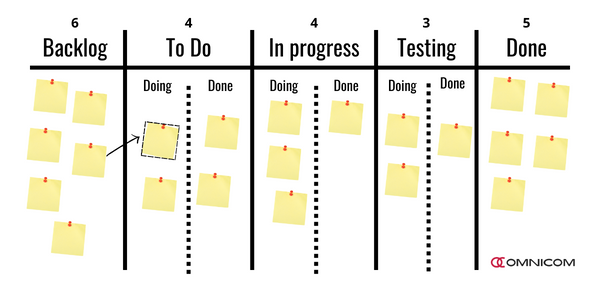

Kanban is a system that focuses on optimizing the flow of work through visual tools. It originally comes from the automotive production environment (Toyota Production System), but since the beginning of this century it has also been used for services. Its key elements are a visual board, task cards and a work in progress limit (WIP limit).

Where can Kanban be used?

Kanban is used in various industries and projects where it is necessary to manage and monitor the flow of work. It is often used by teams working on software development, production, administration or marketing. The reason for its popularity is its ability to adapt to changing conditions and improve processes based on real work flow. You can implement a Kanban board in a simple form in the form of a physical board with self-adhesive labels (Post-it), but also in an electronic format with the help of various software tools.

What are the basic elements of the Kanban system?

The basic elements of Kanban include:

- Visual table: Provides an overview of the work status and enables easy tracking of tasks.

- Task Cards: Represent individual tasks or items that move through the various steps of the process.

- Work in progress limit (WIP limit): Determines the maximum number of tasks a team can work on simultaneously. It prevents the team from getting overwhelmed and improves the work flow.

How to use Kanban?

For the successful use of Kanban, it is important:

- Identifying the process / Value stream: Value stream mapping is the process of naming the value-added steps that a team or worker takes from start and complete a certain job for a customer.

- Determining the scope: It is necessary to clearly determine what scope of the value stream you want to focus on, control it and visualize it on the Kanban board.

- Defining the individual steps of the process: Helps to structure work and identify transitions between individual steps.

- Determining the limitation of the work in progress: Prevents the team from being overwhelmed with tasks and increases the efficiency of the work.

- Monitoring the flow of work and regularly checking the process: Monitoring the status of tasks and their movement in the process will allow you to see bottlenecks, obstacles and identify places where the team is overwhelmed.

- Regular monitoring and process improvement: Helps identify opportunities to optimize work flow and increase team effectiveness.

What are the benefits of Kanban?

The benefits of Kanban include:

- Simplicity: A board, cards and a basic setup are enough for easy use of the Kanban. Also, everyone can get involved almost immediately.

- Flexible Workflow Management: Kanban allows teams to quickly respond to changes and optimize work flow based on the current situation.

- Difficulty identification: A visual table allows for quick identification of problems, obstacles, limitations and waste in the process.

- Process improvement: Continuous monitoring and improvement of processes (Kaizen) increases the efficiency of the team and the quality of outputs.

- Better communication and collaboration: A visual approach encourages open communication within the team and improves collaboration between team members and beyond.

- Increased customer satisfaction: Better planning, more efficient use of resources and quick delivery of results contribute to higher customer satisfaction.